Heat stabilizer is one of the important categories of plastic processing additives. Due to the poor thermal stability of PVC, corresponding stabilizers must be added to repair the defects of PVC chain and absorb HCl produced by PVC dechlorination in time. The birth and development of heat stabilizer are synchronous with PVC resin, which is mainly used in PVC resin processing. Therefore, heat stabilizer is closely related to the proportion of PVC resin and soft and hard products in PVC. In the process of production and processing of heat stabilizer, lubricant (such as polyethylene wax) is also indispensable. A good lubrication system has low volatility, good demoulding and flow performance, and can improve the high-temperature stability of the stabilizer, prolong the thermal stability time, reduce the precipitation of impurities and improve the weather resistance of the product.

Calcium zinc composite stabilizer is one of the heat stabilizers. The lubrication system of calcium zinc composite stabilizer is based on cost factors. Most companies use polyethylene wax as lubricating wax. Sainuo pe wax can effectively improve the fluidity of PVC heat stabilizer processing process, increase the extrusion efficiency of PVC products and improve the surface gloss of products; It can effectively control the agglomeration phenomenon in the processing process of PVC heat stabilizer; And effectively solve the precipitation phenomenon of PVC heat stabilizer in the process of processing products.

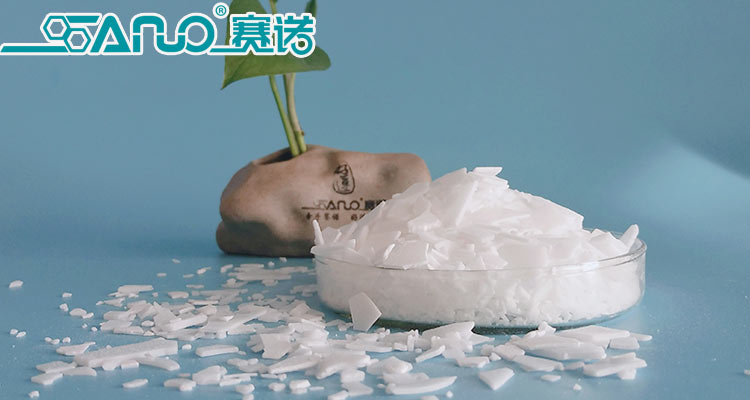

Polyethylene wax, i.e. PE wax, low molecular weight polyethylene, is directly polymerized from ethylene. The products synthesized by different synthetic processes and catalytic systems are different in molecular weight, molecular weight distribution and molecular chain structure, and the performance of corresponding products will also be significantly different. PE wax is usually white powder, with an average molecular weight of 1500-5000 and a melting point of 100-120 degrees. It has excellent external lubrication effect in PVC processing, and can effectively improve the fluidity, yield, dispersion, surface brightness and demoulding of PVC processing. Because of its large molecular weight, high melting point and good high temperature stability, it shows strong external lubrication effect under high temperature and high shear conditions.

Polyethylene wax products can effectively improve the thermal stability of PVC and the fluidity in the processing process, increase the extrusion efficiency of PVC products, improve the surface gloss of products, and effectively reduce the precipitation phenomenon in the processing process of PVC products.

At present, most PE waxes in the domestic market are divided into several types:

1. PE wax is synthesized by ethylene homopolymerization. The PE wax produced by this method has good external lubrication performance, high gloss, narrow molecular weight distribution and very stable quality.

2. The by-product of ethylene polymerization process, commonly known as sub brand wax, is PE wax purified through refining process. The product has low viscosity, high melting point, excellent external lubrication performance and low price, but the quality fluctuates with the changes of raw materials and process. Due to the characteristics of refining process, it is inevitable that there will be more low melting point components in the product.

3. PVC thermal stability low molecular weight polyethylene cracking product, commonly known as cracking wax, the cracking process is simple and easy to operate, but the molecular weight distribution of the product fluctuates with the production process, the quality is relatively good, and there will still be a small part of low melting point components.

Qingdao Sainuo Chemical Co.,Ltd. We are manufacturer for PE wax, PP wax, OPE wax, EVA wax, PEMA, EBS,Zinc/Calcium Stearate…. Our products have passed the REACH, ROHS, PAHS, FDA testing. Sainuo rest assured wax, welcome your inquiry!

E-mail:sales@qdsainuo.com

sales1@qdsainuo.com

Adress:Room 2702,Block B, Suning Building, Jingkou Road, Licang District, Qingdao, China

Post time: Dec-01-2021